Welcome to the home of 3DMBC!

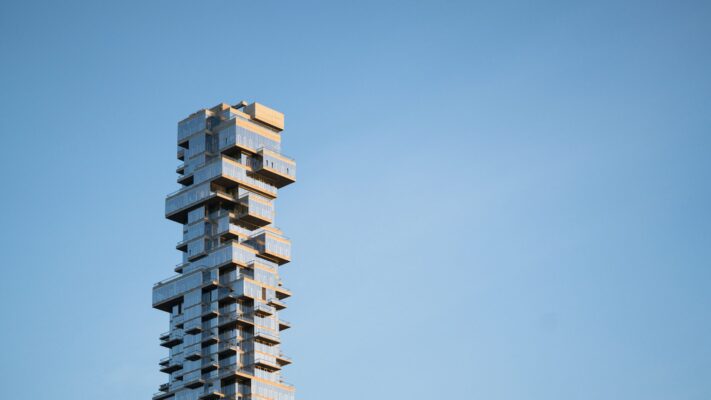

The group focuses on the development of optimised steel connections for modular building systems (MBS) aiming to embrace resilience and sustainability in the construction sector.

The work integrates simulation-based engineering science combined with large and full-scale experimental methods for optimising the structural and material performance. Current topics include structural topology optimisation (STO) for material reduction and design for additive manufacturing (DfAM) together with member size optimisation for tall modular buildings.

The aim of this project is to design and test computationally and physically newly optimised 3D printed connections for modular building systems in order to understand their structural behaviours and practicability.

The core objective of the project is to recognise the design limitations of the current modular construction, and thus design innovative connection prototypes in terms of adaptability and flexibility in handling and installation.

Advanced structural topology multi-objective optimisation tools and methodologies are employed to develop such prototyped designs. Some connection components are 3D printed, following examination of their metallic alloys and material mechanical properties. The final products are structurally assessed through static and fatigue laboratory testing simulating normal and extreme loading conditions. Another objective of this study is to develop installation, maintenance and dismantling practices tackling the challenge of modular co-ordination to eliminating risks and fostering reuse.

How can we improve time and efficiency of the delivery of construction projects through innovative connection and member design?

How can we best use advanced emerging technologies (e.g., BIM, RFID-tags, integrated sensors, to name a few) to add value in the design and manufacturing of such connections?

The benefits of additive manufacturing are widely discussed but transforming it into a successful industrial or end-user product is a challenge to all disciplines along the product development process.

Designers and engineers need strategies to identify the right components, tools, and methods for an efficient design process for using the freedom of design to create benefits for users as well as for the manufacturer. Production engineers have to assess Manufacturing Readiness Levels, implement AM machines into the existing production chain, ensure an efficient operation and establish quality assurance and control mechanisms. Examples for AM-specific topics on the economic side make-or-buy-decisions, supply chain organisation, new business models and converting Unique Selling Propositions will be investigated.