Project summary

Project title

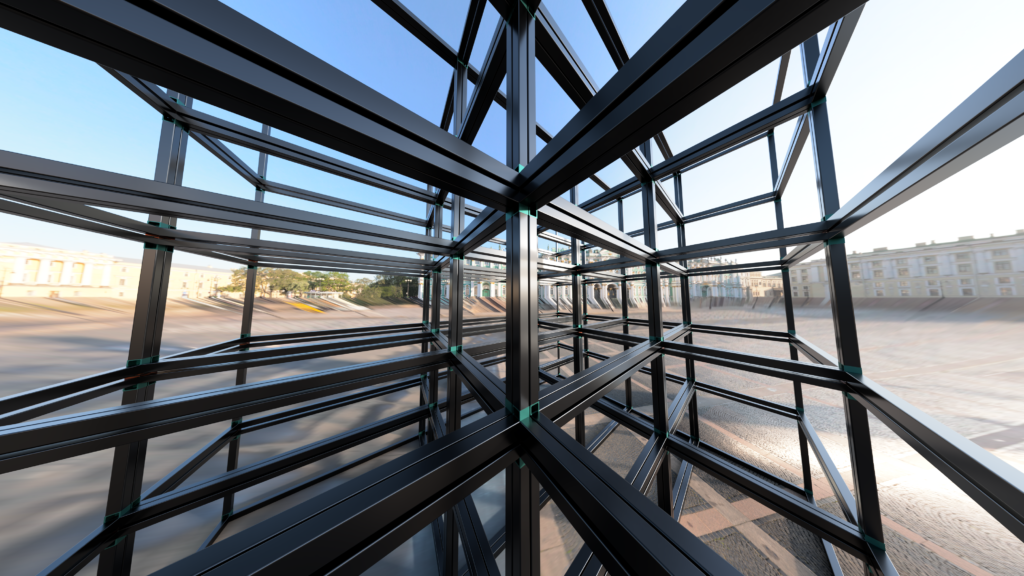

Smart Steel Connections for Modular Building Systems

Project lead

Dan-Adrian Corfar

In collaboration with:

SC4

Tun Abdul Razak Research Centre (TARRC)

2SMArtEST

University of Calabria

Modular construction can rise to the challenge of ongoing housing crises or climate change, but more functionally and structurally performant building systems are necessary.

Despite facing lower uptakes than what many initial projections anticipated, modular building projects have started to gain traction again as the construction industry is seeking faster, cleaner, cheaper, and most importantly, greener solutions for the built environment. Furthermore, as the modular construction industry is headed towards the adoption of a platform-based approach by harnessing opportunities of Modern Method of Construction (MMC) and Design for Manufacture and Assembly (DfMA), one of the key enablers for a successful implementation is the development of smart and high-performance inter-module connections, which represent the interfaces between structural sub-assemblies and govern construction, deconstruction, and structural behaviour of modular building systems (MBS).